Harry Thorpe

Harry Thorpe

Engineering Manager

Experienced Research and Development Manager, currently working on innovative robotic solutions within the oil & energy industry @Process Vision. Enjoys leading a cross-functional team solving technical problems and delivering regular releases for both hardware and software projects. Skilled in agile management (Scrum), 3D CAD/CAM, design for manufacture, software development and ground-up system architecture design. Strong engineering professional with a first class bachelor's degree from the University of Reading. Experienced working in start-ups and knowledgeable of development strategies making the most of available funding.

01.

About Me

Highly motivated self-starter with a proven track record of taking a product idea through to production. Broad experience gained over the years of different disciplines, designing the architecture, developing complex systems to varying technical readiness levels, while being commercially aware, customer facing and leading a highly cross-functional team of engineers over the last 6 years. Currently the Engineering manager @Process Vision, overseeing multiple Innovate UK and internal projects at a company specialising in robotic solutions, utilising machine learning, for the oil and gas industry.

02.

Experience

- Engineering/R&D Manager

Process Vision

- Lead Engineer

Process Vision

- Robotics Engineer

Process Vision

- Teacher and Course Designer

Tech Camp

Process Vision

Created an API and multiple front-end applications to provide a greater customer experience. This integrated my previously developed ML predictions.

Led and implemented the adoption of agile management methodology company-wide.

Mentored my team in iterative engineering strategies and risk mitigation (Agile Unified Process).

Supported the MD & Operations Director with business development activities.

Experienced with taking development projects to market and recruiting multi-disciplinary engineers.

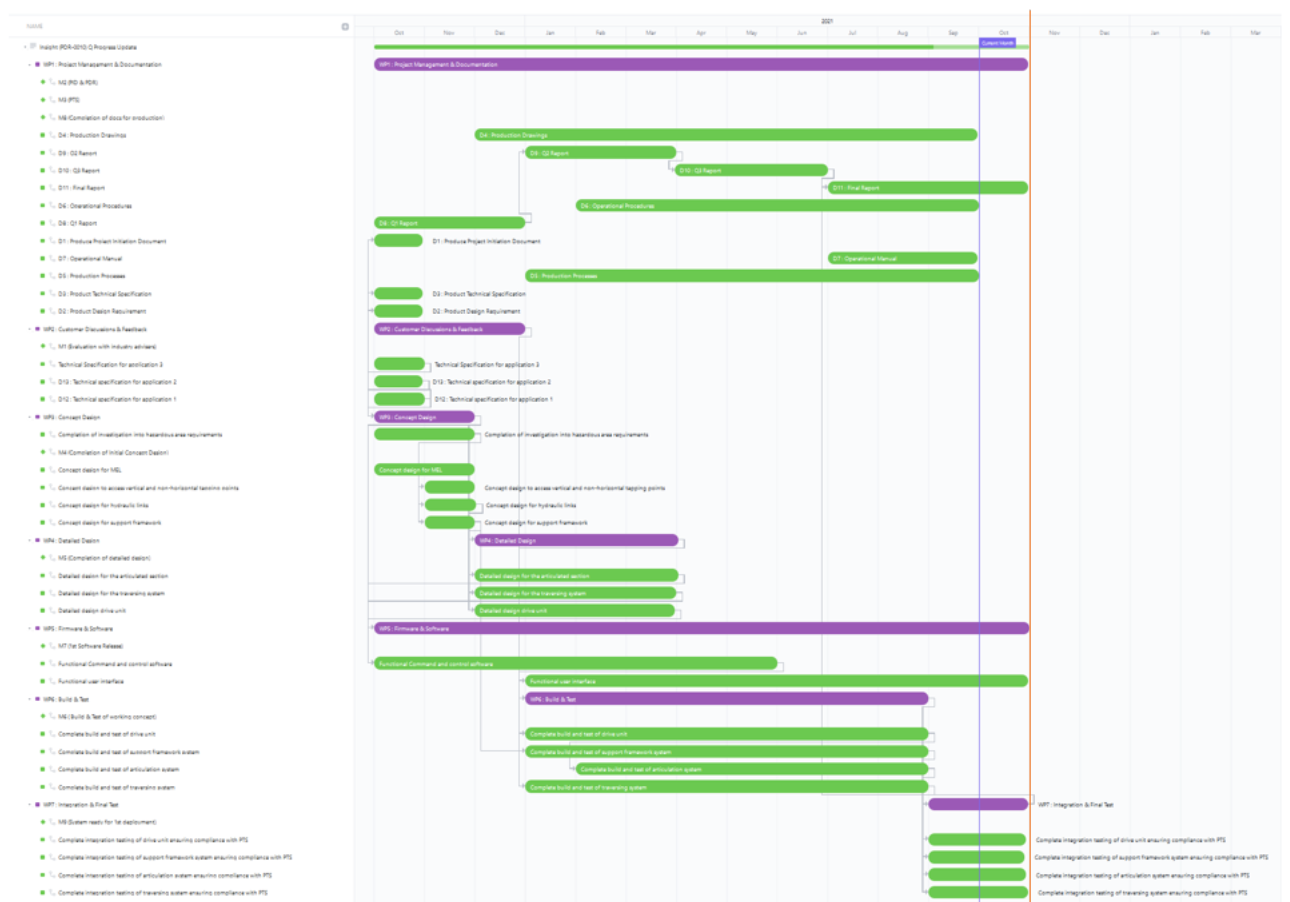

Successfully managed and delivered two research project funded by Innovate - UK (1: Further improving a previous robotics system for use in hazardous environments at high pressure elevating the project from (Technology Readiness Levels) TRL 4 to TRL 9 - 2: Developed a borescope system (TRL 2 to TRL 9) for use within high pressure applications for inspection and measurement)

Created key business practises and coached teams on agile principles with a focus on customer requirements.

Contributed to regular management meetings with a focus on business strategy and maximising resource.

Introduced and coached teams on task management systems to enable full utilisation of resource.

Performed budget reviews and monitored project spend forecasts for external reporting.

Promoted machining services for external customers, resulting in additional income to the business.

03.

Projects

Process Vision - Innovate UK

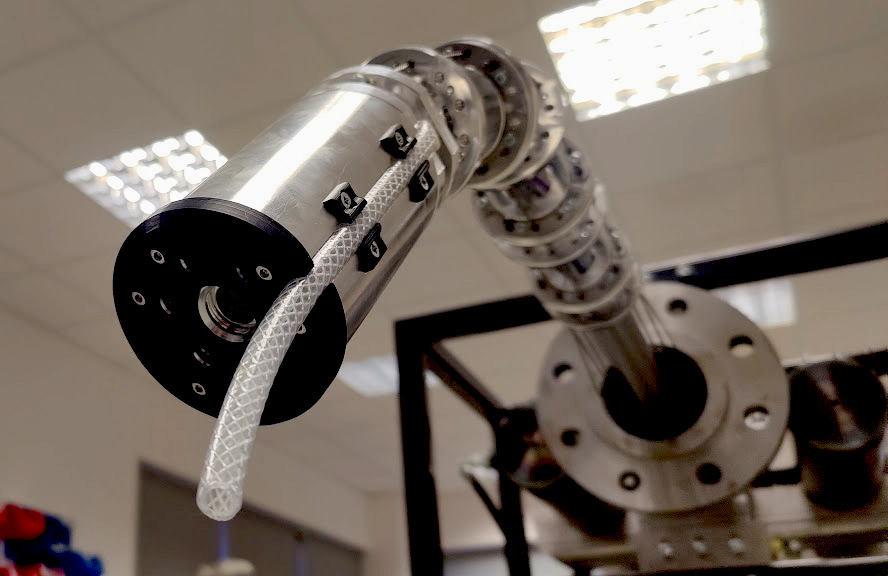

Robotic Inspection - Insight

Sucessfully delievered a Innovate UK project to develop a robotic inspection system. This was an espcially tricky project due to the required certifications and application pressure of over 100barG.

Process Vision - Innovate UK

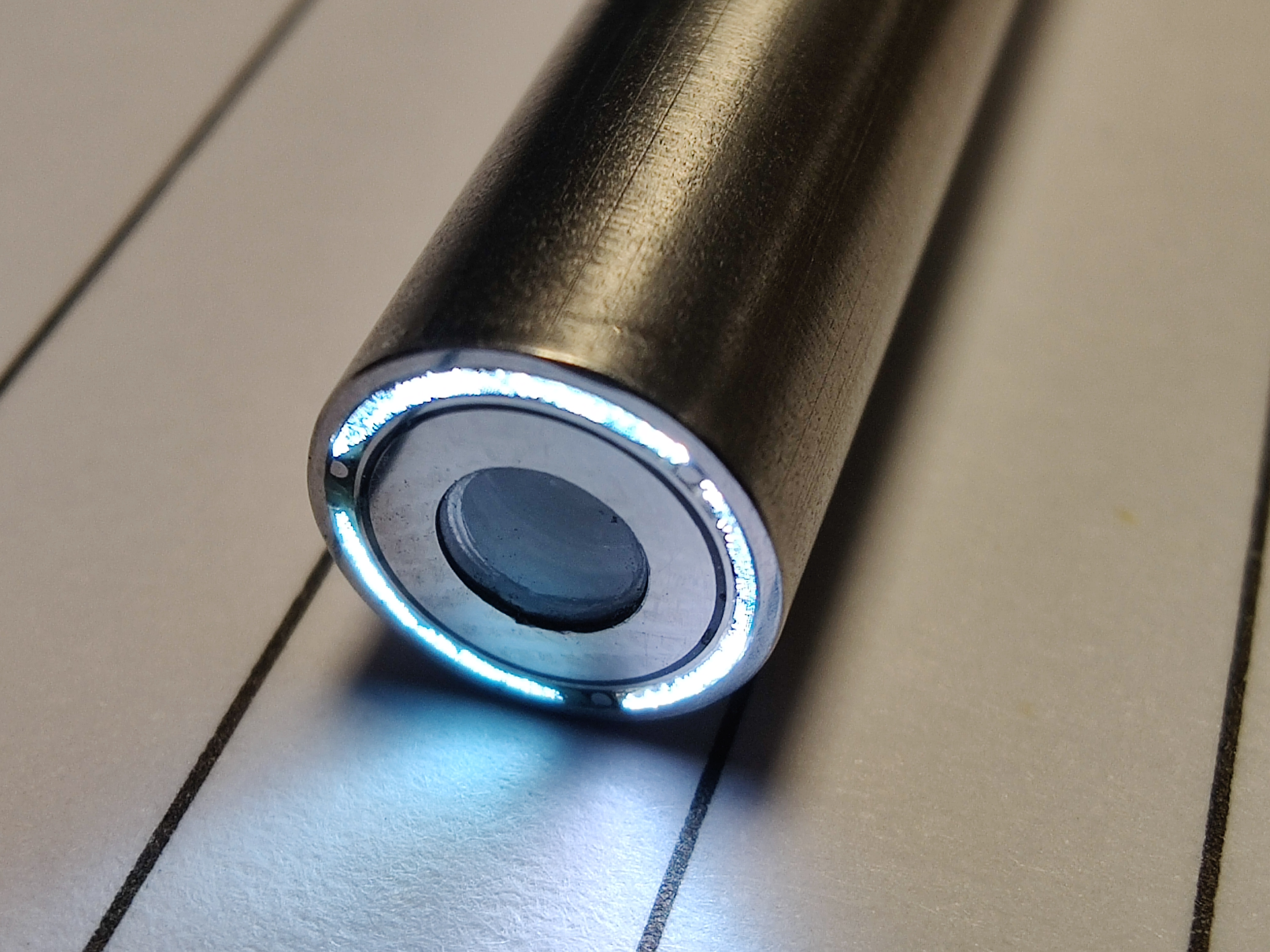

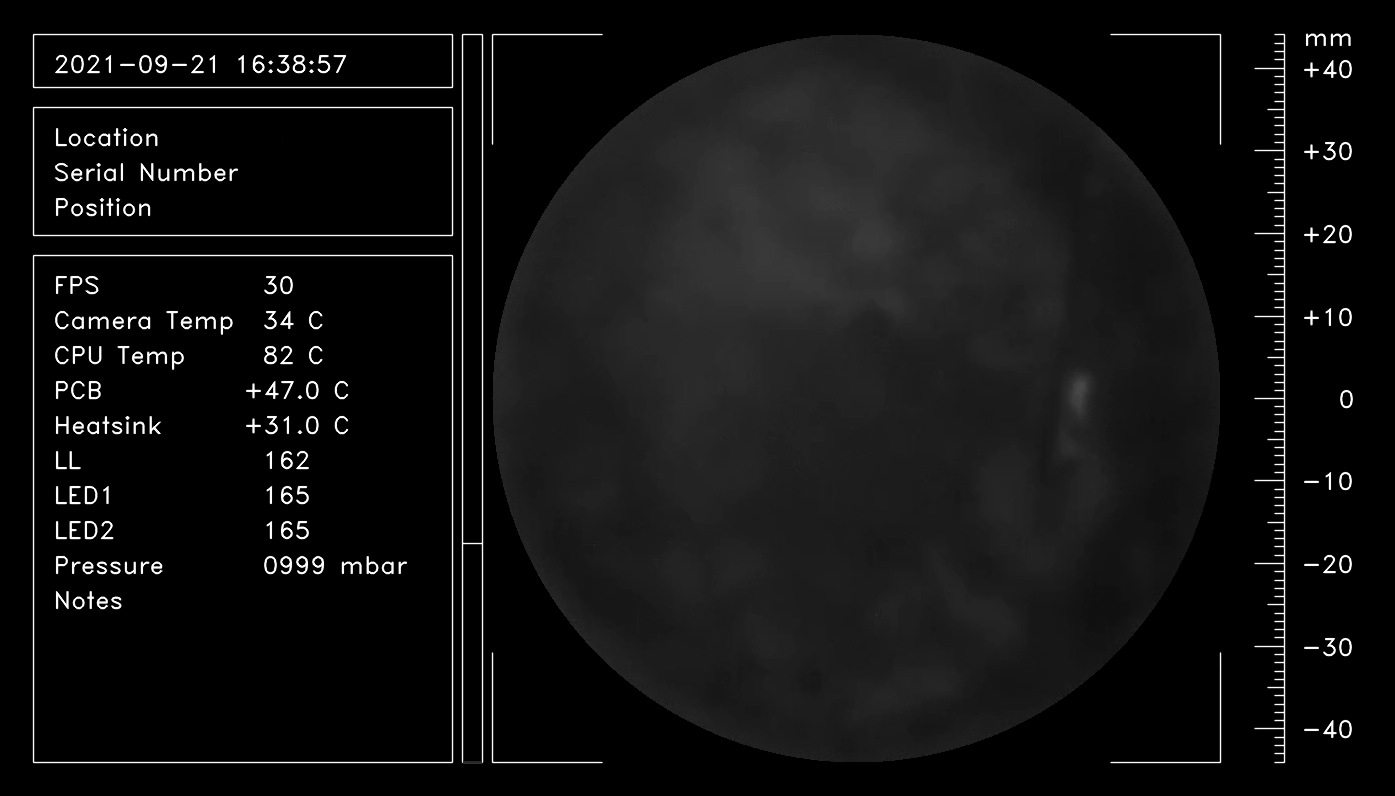

ATEX Borescope Camera - LineVu 200

Lead a small team to complete a Innovate UK project to develop a borescope based inspection camera, extending the companies core product LineVu 100

Process Vision

ATEX Pipeline Camera - LineVu 100

Lead the continued development of a hazardous area certificated, pipeline monitoring system. Designed and Developed the infrastructure to provide continuous recording and daily analytics, performed by ML and presented in a React.js portal.

04.

Other Work

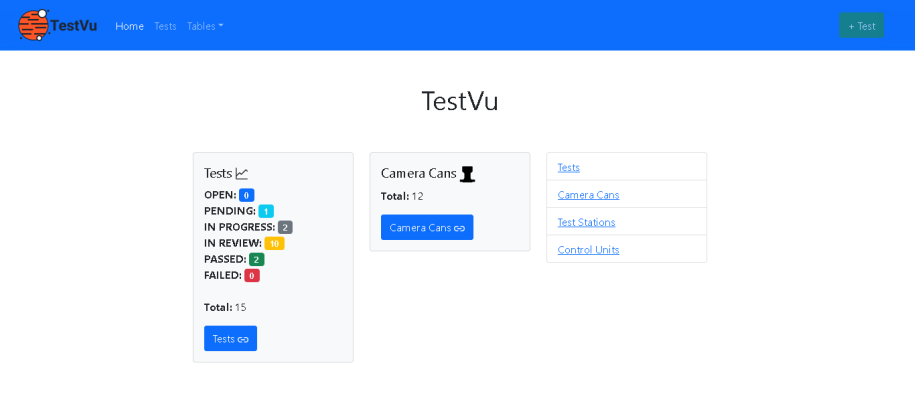

Internal Production Tool

A react.js application to provide an internal production tool to process product pressure tests.

Software Development

Global Deployment Architecture

A hardware and software system which allowed for systems installed internationally to be remotely commissioned. The architectural solution took into account our end-users (gas production sites) and provided a route for on-going maintenance and updates.

Software Development

GraphQL API

A authenticated and authorized API which provided a central endpoint for many internal tools and end-user applications.

Software Development

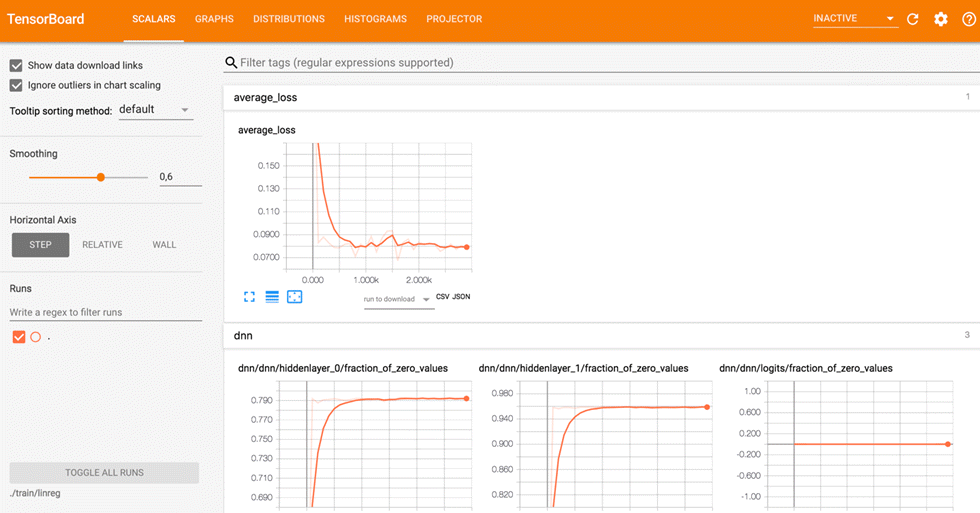

Novel Machine Learning

To unlock value in a product, I implemented a machine learning (CNN) algorithm to provide classifications on video data and then present this to the customer in a daily update to various roles within the customer's organisation.

Software Development

OpenCV/Gstreamer Camera RTSP Server

A deployed C++ program to take a live video feed, apply image transformations and stream it over a network using RTSP (Gstreamer)

Software Development

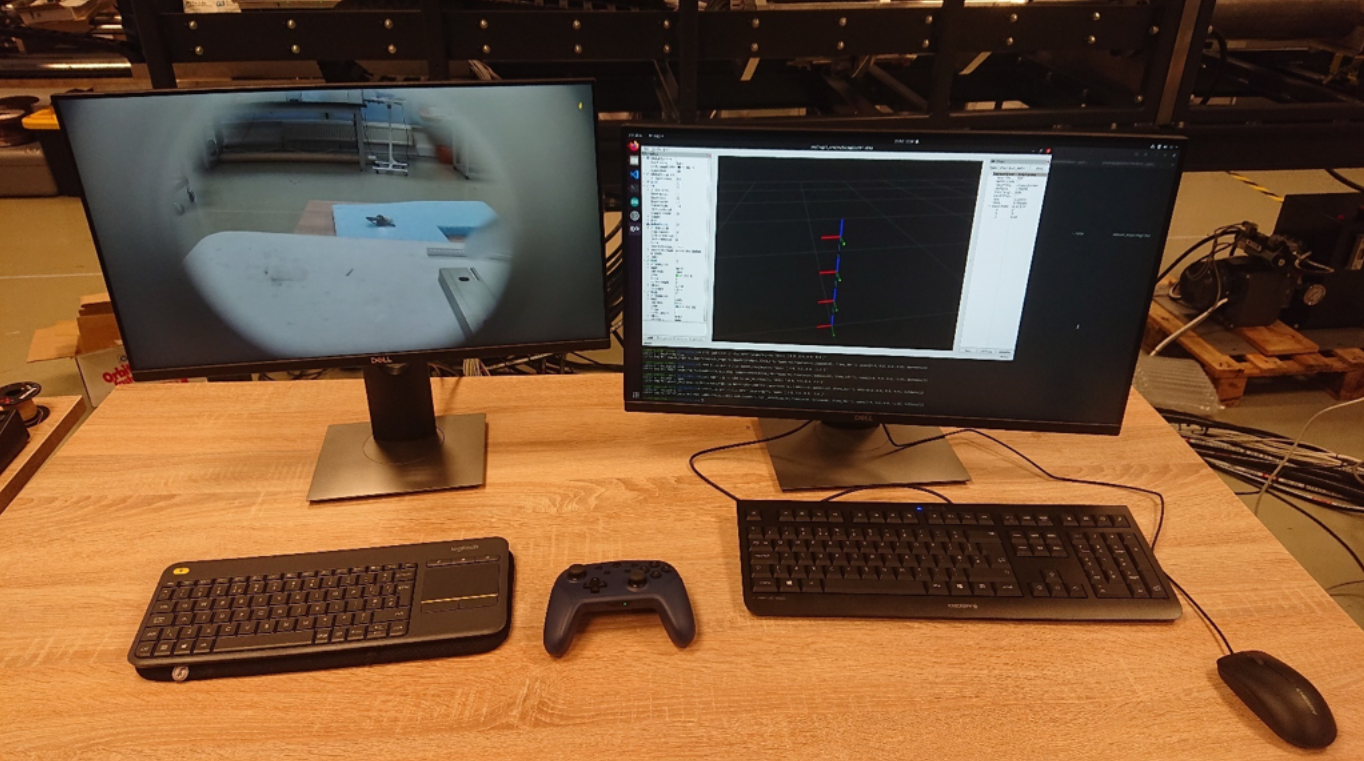

ROS Based Control System

A robotic control system, developed in ROS to control a hyper-redundent cable-driven robotic inspection system

Robotics

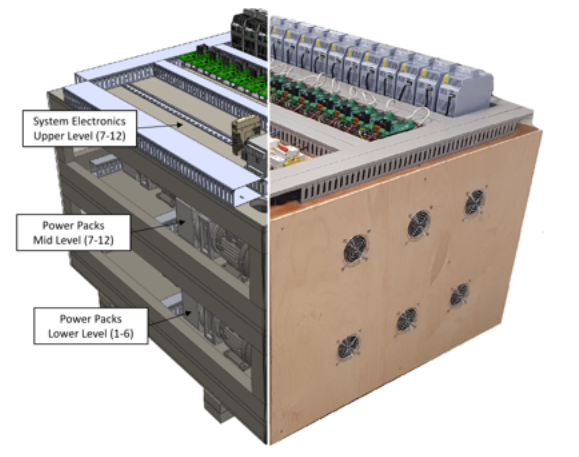

Multi Variable Hydraulic Pump System

As part of a project to develiver a robotic inspection system, we designed and built a multi variable hydraulic pump system. Each low volume pump was controlled by a VFD and interfaced to through custom MODBUS converters, allowing ROS control.

Control System

Management of Multiple Innovate Projects

Through the develvery of multiple Innovate UK projects, I gained further project managment skills. Collobrating with acedemaic partners from the University of Reading and producing acedamic papers.

Management

Not only theoretical !

After joining Process Vision, one of the first tasks was to deliever a large robotic project. The projects budget was not going to permitted the level of iteration required. I procured a CNC machine in and performed all the machining myself and later trained new staff to allowing me to focus on other engineering aspects.

Mechanical

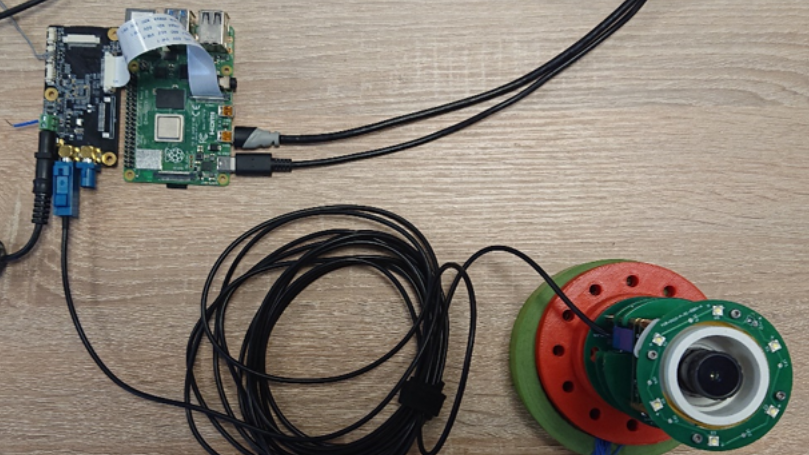

Supporting Vision Electronics

On a regular occasion, a custom assembly would be required to be developed to support a machine vision camera and it's peripheral devices (LEDs, IMU, etc.)

Electronics

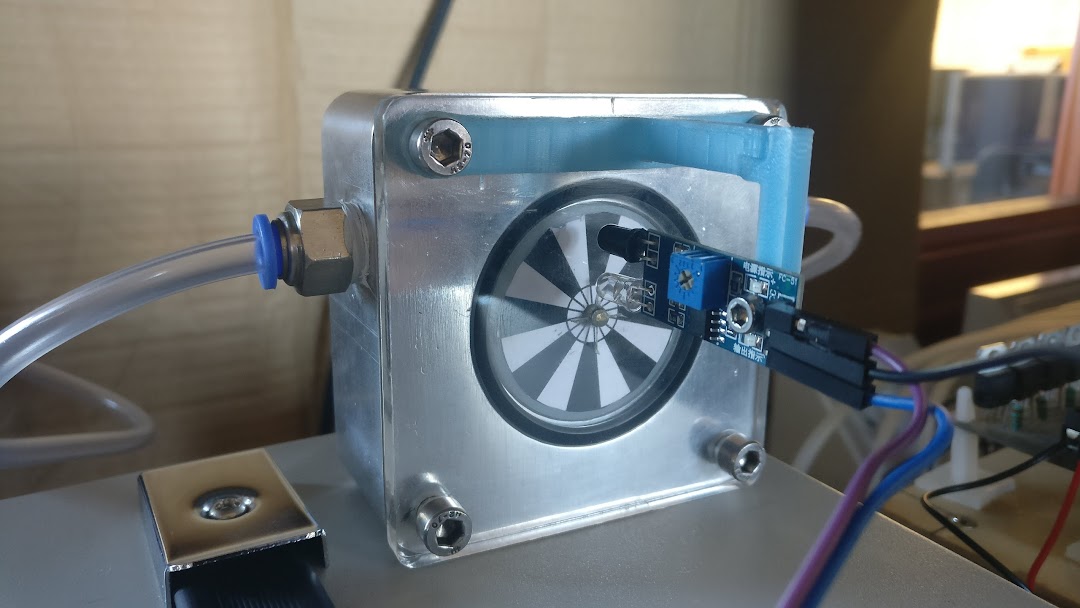

Custom Flow meter

During a soft robotics project, a flow meter was required for integration into the control system at a low cost. With the limited budget, I designed and machined a very basic flow meter.

Mechanical05.

Contact Me

Designed & Developed by Harry Thorpe